Why choose a brushless motor?

There are two types of electric motors in model making: brushed carbon motors and brushless brushless motors . While cheaper brushed motors are still used for entry-level electric vehicles or crawlers, brushless motors have won the hearts of RC pilots who love miniature car competitions.

In fact, brushless motors are perfectly suited to miniature car competitions due to their numerous advantages:

- no friction of the brushes therefore less wear, better motor longevity, lower electrical consumption and better efficiency

- no need for break-in so they are ready to use right out of the box

- less maintenance, just dust them from time to time

Brushless motors have therefore naturally taken a prominent place in RC modeling, however, choosing a motor suitable for your electric vehicle can seem complicated. We will therefore explain in this article what its characteristics are, how to choose it and how to adapt it to the car via an ESC controller.

How to choose your brushless motor?

Engine size

The size of the brushless motor is the first criterion to take into account. Indeed, the size of the motor is always proportional to the size of the radio-controlled vehicle. It is therefore important to choose an engine adapted to the scale of the vehicle . For example, a 1/8 buggy motor is far too large to be installed on a 1/10 buggy .

The relationship between torque and engine speed

The kv indicate the number of revolutions/min per volt and therefore the theoretical maximum speed of the motor . For example, a 3,800 kv motor will be able to run at 3,800 rpm for 1 volt, or 28,120 rpm with a 7.4V Lipo battery . You can also find a T number attached to brushless motors, this is a reference for pilots in RC competitions.

You should know that increasing the kv speed comes at the expense of torque. You must therefore choose the best report based on your practices. Here are some guidelines to know which speed to choose for your engine.

On track :

- on a 1/8 scale you can choose a number of revolutions/min per volt around 2600 kv

- on a scale of 1/10 , for leisure 4500 kv, for competition 6500 kv

Off road :

- on a 1/8 scale you can choose a number of rpm between 1900 and 2200 kv

- on a scale of 1/10, for leisure 3800 kv, for competition 5000 kv

What does the T stand for?

The T is mainly used during RC competitions. Brushed carbon motors were classified by revolutions (T) according to their winding. By habit, we kept this designation to indicate the power of brushless motors.

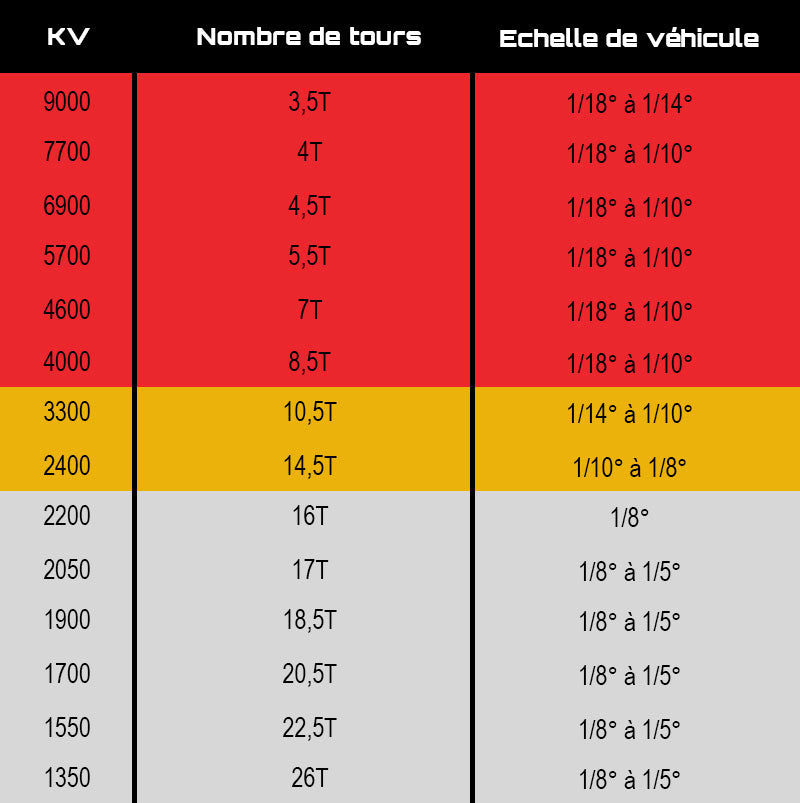

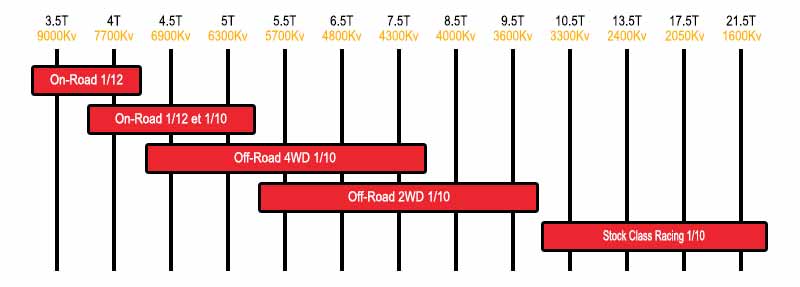

Here are two diagrams to help you convert kv to T:

The number of poles

Pairs of magnets are glued to the motor rotor. They generate magnetic poles which can be 2, 4, 6, etc. These poles directly influence the torque and the speed . A motor with a low pole number will spin faster than a motor with a high pole number but will have lower torque. For example, with the same controller, a 2-pole motor will have a rotation speed twice as high but a motor torque twice as low. The majority of controllers are designed for 4-pole motors.

Motor with sensored or sensorless sensor?

Motors with sensors (also called sensored motors ) are more expensive than their counterpartswithout sensors ( sensorless motors) . By indicating the rotor position to the controller, the sensor improves the smoothness, torque and speed of the motor . However, sensored motors are rarely waterpoof, this is their main disadvantage.

Please note, to take full advantage of the advantages of a sensored motor, you must associate it with a SEC controller compatible with sensored .

Maximum motor consumption (W)

The maximum consumption of the motor, indicated in watts, is important to remember when choosing the controller because it must be capable of delivering this power.

How to choose your ESC electronic variator

What is an electronic variator used for?

The ESC controller (electronic speed controller), also called electronic variator , is an essential element for the operation of the engine . It connects the motor to the battery and delivers the necessary current according to the motor's demands. It is during acceleration and braking that the engine consumes the most; the rest of the time consumption is relatively low.

What amperage for my ESC?

The first thing to check when choosing the variator is that it meets the needs of the motor. Wattage is determined by the formula P=UI. As the voltage U is constant (7.4V for a LiPo battery), a motor with a high maximum consumption will have to be coupled with a controller which delivers a lot of amperage.

To choose your ESC , you must therefore calculate the amperage necessary for the proper functioning of the motor. For example, the calculation to be carried out with a motor which consumes 463W and with a voltage of 7.4V is: I=463/7.4=62.6A. You must always choose a drive with an amperage greater than the value obtained with the calculation, in the previous example we can take an 80A controller. In fact, an amperage that is too low risks causing the drive to heat up too much. Sometimes, the continuous amperage supported is not indicated with the variator, in this case you must look at the minimum number of revolutions accepted (indicated in T).