Today, variators are installed on most electric motors . This includes a wide range of machines ranging from basic electrical appliances used by individuals, to large industrial installations, pumps, machine tools, etc. We can therefore see how important this speed control technique is in motors and in particular those of powerful electric RC vehicles . We will present to you the role of a variator and how to choose it .

What is a variator and what is its role?

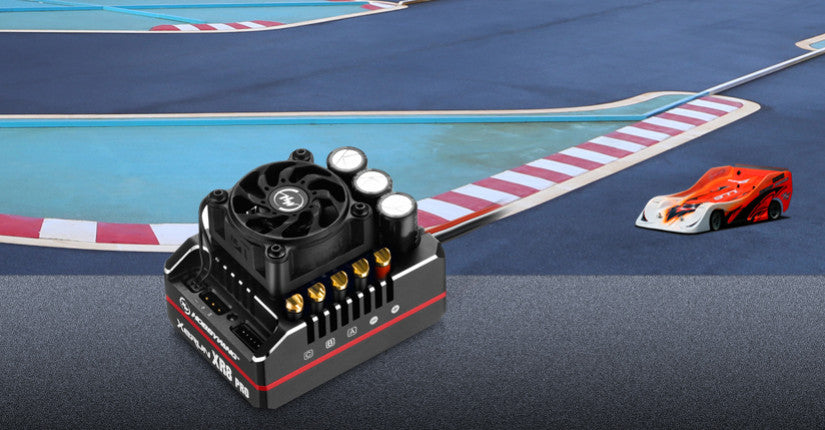

The variator, also called electronic speed controller (ESC) can be thought of as the brains of our vehicles, a complex processing unit that allows them to move forward or backward with the pull of a trigger. It regulates the power of the electric motor , allowing it to accelerate from 0% to 100%, in response to control signals coming from the receiver (which it also powers).

Think of them as a middleman. After receiving an acceleration instruction from the wireless transmitter , the receiver will instruct the speed controller to accelerate the car to 80% of its power. The electronic controller takes energy from the battery , adjusts it according to the instruction before transmitting it to the motor, which in turn turns to move the car forward. These instructions are updated several times per second, with the ESC continually modulating motor power according to the rider's needs.

What is the BEC used for?

The BEC eliminates the need for a separate power supply for the receiver and servos . It's a voltage regulator that sends part of the battery's power, usually 6V, to the receiver to then power your servos. Some dimmers can be modified to regulate the voltage to 7.4V or 8.4V instead of 6V. It also has a secondary function: if the battery that powers the motor reaches its minimum voltage, the BEC (Battery Eliminator Circuit) reserves the energy necessary for the operation of essential components such as the receiver and servos which allows you to keep the control of your car in all circumstances. There are also UBECs which have the same role as the BEC but with the ability to send larger currents to the servos.

How to choose a dimmer?

There are two main categories of drives: brushed drives and brushless drives . The first are designed to work with a brushed motor , the second with brushless motors . There are several other things to consider when choosing your dimmer. Size and weight are also parameters to take into account depending on the model and your use.

- The maximum voltage (expressed in V) of the battery must not exceed that of your drive.

- Its maximum amperage (expressed in A) which must not exceed that of your motor otherwise it may suffer damage.

- The maximum amperage of its BEC (expressed in A) must be able to be supported by the receiver.

- The maximum voltage of its BEC (expressed in V) must be able to be supported by the receiver and by the servos.

We recommend using drives with a maximum amperage between 50A and 100A for 1/10 cars, between 100A and 150A for 1/8 cars and 150A to 200A for 1/5 cars. To ensure proper operation and a long lifespan for the drive, choose a model with an intensity approximately 50% higher than what it will have to support. Example: Your motor consumes 40A, choose a controller supporting up to 60A.

How to use a variator?

Powering up the drive

Dimmers often feature the vehicle's main power button . This can be a single button or a small two-position switch. Other units are powered on as soon as you plug in the battery.

Wiring of the drive

The variators are at the center of the electronic system of an RC model. As such, they have connections to the battery, motor, receiver and sometimes other units. The battery connector will be the most familiar to you, this is usually two thick wires (often one red and one black) terminated in an XT60/EC3/Tamiya/Traxxas/deans/etc connector.

Brushed drives will usually have a pair of wires powering the motor while brushless drives tend to have three wires. There will also be a thin, multi-wire cable with a 3-pin connector on the end that plugs into the receiver.

Battery Chemistry Flexibility

A single type of battery connector can be used for multiple battery chemistry types ( NiMH , LiPo , Li-Ion etc.) so if it is not capable of automatically detecting the battery type, it is important to manually adjust the variator. Dimmers that require adjustment, usually have a jumper that must be moved according to the manual or an information sticker on the side.

Setting programmable dimmers

Basic drives have limited configuration, managed by a start button or jumper setting. Their adjustment is often limited to the end of travel and the neutral position in conjunction with the transmitter.

More expensive dimmers can be configured in more detail with a "set" button and feedback LED found on the unit or on a junction box next to the power button. The manual included with the unit will provide instructions on how the adjustment knob and read LED can be manipulated to customize the settings.

The settings of the most advanced dimmers can be adjusted via a plug-in programming card , a special USB adapter plugged into a computer, or a wireless dongle that connects to an app on your smartphone where settings can be changed. Settings that can be adjusted include LiPo cut-off voltage, operating mode, reversing force, thermal cut-off temperatures, BEC voltage, drag/speed brake function, throttle curve and many, much more.